Technical information

What is eddy current testing?

An eddy current tester is intended to detect the presence of foreign substances in a test object and inspect the condition and materials of the test object by a magnetic field produced by applying a high-frequency electric current to a coil.

Eddy current testing can be performed without physical contact with test objects and thus quality control can be achieved without destroying/breaking the products.

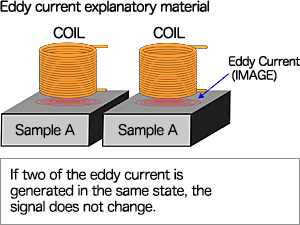

As shown on the left, applying a high-frequency electric current to a coiled copper wire causes an alternating-current magnetic field.

By placing a conductive material near the field, current flows in proximity to the surface of the material. This current is called an eddy current.

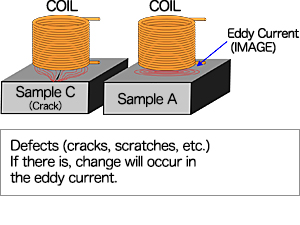

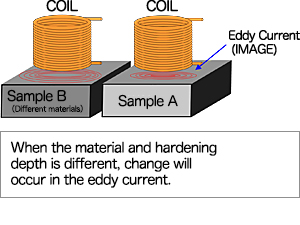

The eddy current causes a new magnetic field to repel the magnetic field produced by the high-frequency electric current. The repelling force differs according to current frequency, material permeability, conductivity, geometry and distance from the coil. By performing various operations, only intended factors (scratching, breaking, material, hardening depth, interval, vibration, dimensions and film thickness) are extracted from the signal.